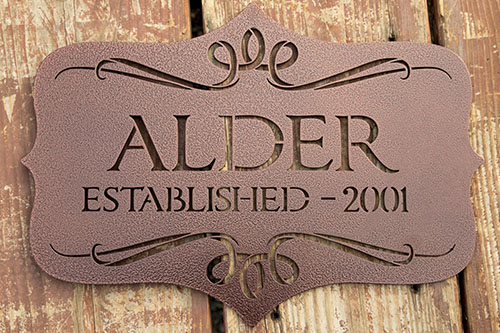

Powder Coated Signs

Powder coated signs are one of the most popular finishing options. Not only does it look visually pleasing, but powder coat also protects the metal from outdoor exposure. At Smith Steelworks, we work to create custom signs that will last for years and years to come. Call (385) 225-4644 to get started on your project.

What Is Powder Coating?

Powder coating is a finishing process that is used on many industry products. Powder coat is a mixture of pigments, resins, and fillers. The powder is applied to the metal sign through an electrostatic spray gun. The sign is then placed in a specialized oven at 400 degrees. This process fuses the powder together and creates a smooth, durable finish.

Benefits Of Powder Coating

Powder coating is twice as thick as paint and provides significant benefits for metal signs. Here are some of the benefits of powder coated signs:

- It is resistant to scratches, chips, flakes, and scuffs.

- Acts as a barrier between outdoor exposure and the bare metal. This keeps the sign free from rust and corrosion.

- The vibrant color will stay looking bright for years to come; even with harsh sun exposure.

- Powder coat is an environmentally friendly process.

- The powder coat is available in a large selection of colors. You can view our colors here.

Powder Coating Process

Sandblast

A fine sand is sprayed onto the metal sign to remove any impurities including: old paint, rust, dirt, and oils. It also creates a profile that will help the powder coat seep into every surface of the metal.

Prime

Epoxy primer is next applied to the metal sign. This helps create a bond between the metal and primer. It also provides an additional layer between the bare metal and the outdoor exposure.

Powder Coat

Lastly, the powder coat is applied evenly across the metal sign. It is then baked at 400 degrees to create a lasting finish. Once the sign has cooled, it is assembled, packaged, and shipped directly to you.